https://www.enginela...d-speed-racing/

When it comes to going fast by modern standards, the Flathead Ford isn’t exactly the first powerplant that comes to mind for most people. Fortunately for us, Keith and Jeff Dorton of Automotive Specialists aren’t “most people.” In fact, we’ve highlighted the Dortons’ work with Flathead Fords several times in the past as you can see HERE and HERE. However, this latest Flathead project is even more outrageous.

Thanks to Jeff Huneycutt at The Horsepower Monster, we get a look inside this Flathead engine build which has everything but the kitchen sink (and maybe even parts of that, in the intercooler system) thrown at it. Using a set of Ardun overhead valve-conversion cylinder heads and a ProCharger centrifugal supercharger, this engine has been in development for over two years, and its owner, Doug Kenny, is looking to make some serious steam on the salt flats of Bonneville while breaking class records.

Developed by Zora Arkus-Duntov (yes, THAT Zora Duntov) as a product for Ford itself to sell, the bean-counters ultimately passed on the project, leaving the Duntovs to manufacture and sell the conversion themselves. While the average Ardun conversion delivered anywhere from 25 to 60 percent gains, the lack of corporate backing and the high final price, as well as some fitment and longevity issues at the time, meant that there were only somewhere between 200 and 250 conversion kits ever built.

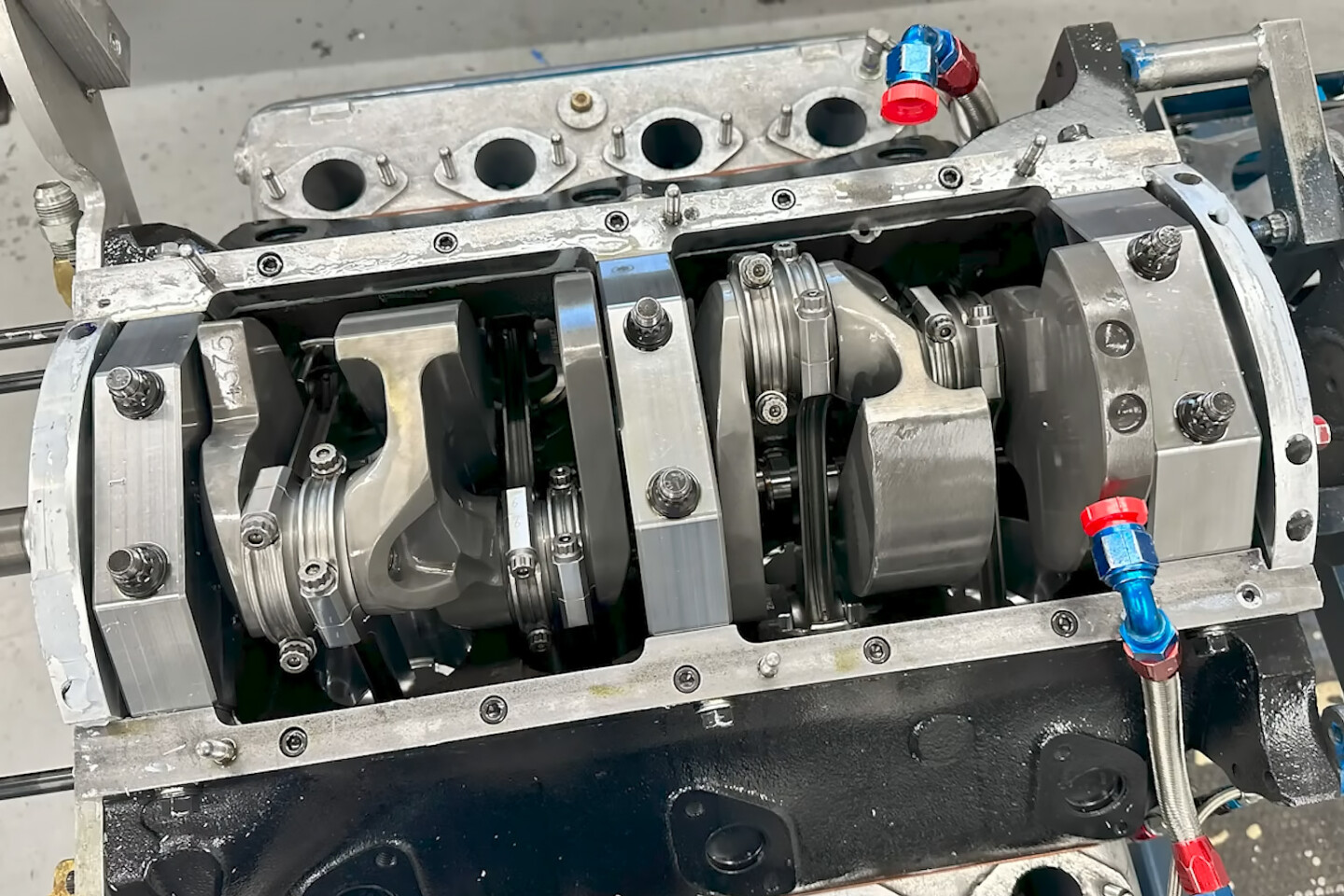

There is a lot to take in here. First, is the fact that there are only three main journals, but they have been redesigned with massive billet main caps and a support rail system. Next are the aftermarket crank and rods. Finally, there are the two semi-circular main seal adaptors allowing for the use of a modern main seal in place of the original rope seal.

As you might imagine, parts for an overhead valve Flathead Ford, looking to go fast, aren’t just sitting around on manufacturers’ shelves, so the rebuild of this engine into its current form was a significant investment of both time and money, with more custom parts than mass-produced ones. Looking to challenge the XXF class, which requires the use of a factory Flathead engine block. Right off the bat, that puts you at a huge disadvantage thanks to only having three main journals.

Rather than use one of the existing main girdle systems on the market for the Flathead, Dorton has instead developed a set of billet main caps that look like they belong on a top fuel Hemi more than a Flathead. The main caps are coupled to a main cap support system that looks like super-beefy oil pan rails. Sitting in the mains is an aftermarket crankshaft, that Dorton has modified to accept modern rear main seals as well as utilize a modern Chevrolet-pattern clutch and flywheel.

Besides the modifications to the main journals and the main seals, the block’s factory oil pump system was blocked off in favor of an externally mounted oil pump. The engine is still a wet sump design, however, with a custom oil pan designed to fit all of the main journal and seal modifications as well as adding precious oil volume to the engine.

The camshaft is a solid roller design featuring a mild .438 inch lift on both the intake and exhaust with 260 degrees of duration at .050 inch of lift on the intake side and 257 degrees on the exhaust. Isky .843-inch solid roller lifters modified from a tie-bar design to a bushed keyway design translate the cam lobe’s motion into vertical motion. Since the engine still relies on the original Flathead splash-oiling design, the rollers utilize needle bearings instead of a solid bushing,

Being an extremely rare cylinder head, no big modifications to them were made, However, they were fitted with a set of modern stainless steel valves measuring 1.875 inches on the intake and 1.550 inches on the exhaust. The rocker arm system isn’t original, but follows the original design that is very reminiscent of an original Hemi valvetrain. Keeping everything under control is a set of Isky Chevrolet valve springs with 225 pounds of seat pressure.

A belt-driven ProCharger F-1R centrifugal supercharger hangs off the front of the engine and is only pullied to provide 10 psi to the intake tract, although the F-1R is capable of significantly more airflow at full song. The supercharger’s outlet feeds directly into an air-to-water intercooler core, that is then attached to a 750cfm blow-through double-pumper carburetor.

On the dyno, the combination sounds about as you’d expect an F-1R-equipped V8 that only spins to 5,800 rpm to sound. However, the sound belies the engine’s output, making it sound easy. Both the horsepower and torque were still climbing at the end of the pull, with both peaks occurring at 5,800 rpm. Realizing 722 horsepower and 654 lb-ft of torque is nothing to sneeze at, especially with only 10 psi.

However, turning it up probably isn’t likely for several reasons. One, the Dortons feel that 722 horsepower is enough to take the XXF class record at Bonneville. Not only will they be going after the blown-gas roadster record at 208.24 mph, but also the blown-fuel roadster record. Two, at the end of the day, it is still a factory three-main block that is north of 70 years old, and probably closer to a century old. And 722 horsepower is significantly more than the highest rating of 110 horsepower from the factory.